Rex LED represents a cutting-edge advancement in solid-state lighting technology, offering superior performance characteristics compared to conventional LED solutions. These high-efficiency diodes feature an innovative semiconductor architecture with quantum well structures that achieve wall-plug efficiencies of 220 lm/W at standard operating conditions (25°C ambient temperature, 350mA drive current). The proprietary phosphor conversion system enables Rex LEDs to deliver exceptional color rendering with CRI values exceeding 95 across the entire correlated color temperature (CCT) range from 2700K to 6500K.

Key thermal management innovations allow Rex LEDs to maintain 90% lumen maintenance after 100,000 hours of operation (LM-80 data at 85°C case temperature), significantly outperforming industry-standard LEDs which typically show 70% lumen maintenance at 50,000 hours. The advanced packaging technology reduces thermal resistance to 2.5°C/W, enabling higher drive currents up to 1.5A in properly designed systems.

Rex LEDs operate within a forward voltage range of 2.8V to 3.4V depending on the specific model and operating conditions. The current-voltage (I-V) curve demonstrates minimal droop characteristics, with efficiency decreasing by only 15% when driven at 1A compared to standard test conditions (350mA). This makes them particularly suitable for high-current applications where maximum light output is required.

The angular color uniformity of Rex LEDs is exceptional, with Δu'v' < 0.003 across a 120° viewing angle. The spectral power distribution shows narrow-band blue emission peaking at 450nm ±2nm with precisely tuned phosphor blends that create smooth, continuous spectra in the visible range. The luminous flux bins are tightly controlled to ±3% variation within each ANSI standard chromaticity quadrant.

Accelerated life testing demonstrates that Rex LEDs maintain 95% survival rate after 10,000 thermal cycles (-40°C to +125°C) and 1,000 hours of damp heat testing (85°C/85% RH). The robust construction resists sulfurization (MIL-STD-883 Method 1008) and passes stringent mechanical shock (1500G, 0.5ms) and vibration (20G, 20-2000Hz) tests.

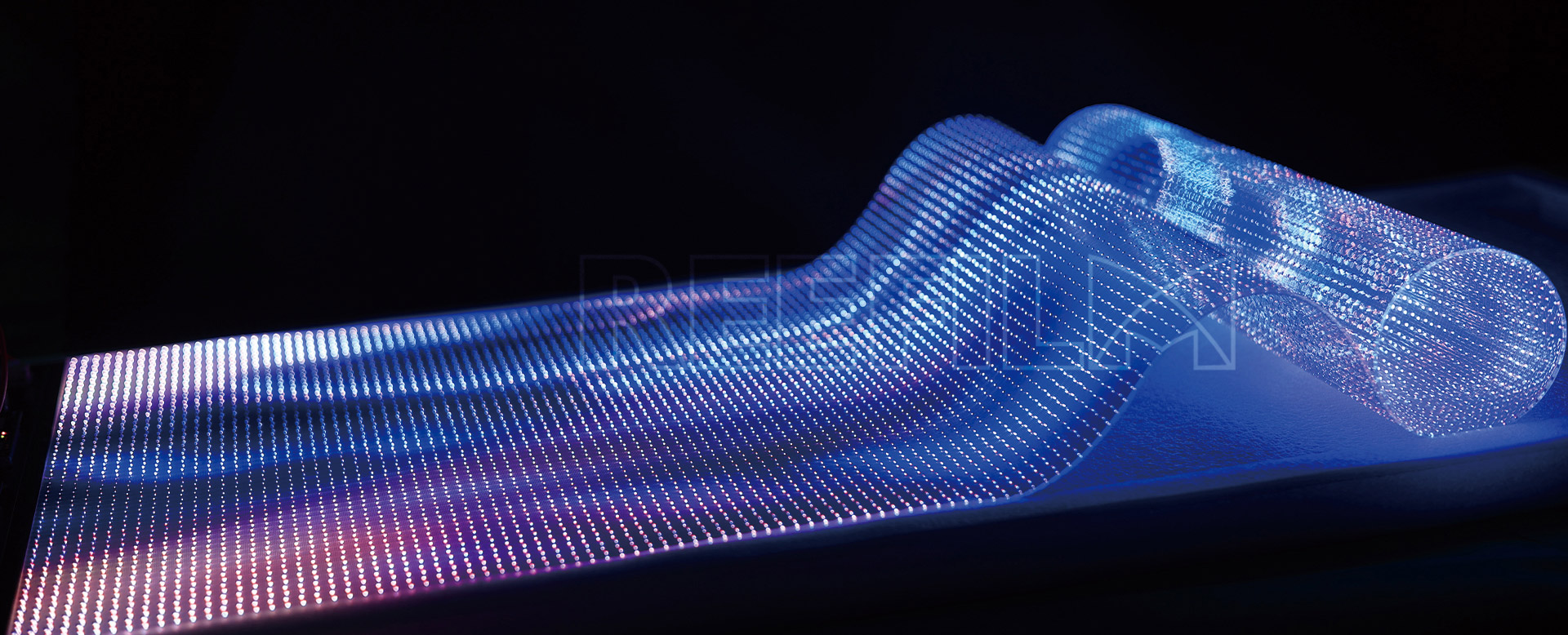

Rex LEDs are transforming architectural illumination with their combination of high output and precise color control. In facade lighting applications, they enable 50% energy savings compared to conventional metal halide solutions while providing superior color consistency (MacAdam 2-step ellipses). The 120° beam angle with smooth falloff creates seamless grazing effects on building surfaces.

The tunable spectrum of Rex LEDs makes them ideal for controlled environment agriculture. Specific models provide PPF (Photosynthetic Photon Flux) of 3.2 μmol/J with optimized ratios of blue (450nm), red (660nm), and far-red (730nm) wavelengths. Grow light fixtures using Rex LEDs demonstrate 30% faster growth rates for leafy greens compared to HPS lighting, while consuming 60% less energy.

Automotive OEMs are adopting Rex LEDs for adaptive driving beam (ADB) headlight systems. The 15,000 cd/mm² luminance enables compact optical designs meeting ECE R112 class B requirements. The instant-on capability (<100μs response time) is critical for matrix beam applications. Rex LEDs maintain performance across the automotive temperature range (-40°C to +105°C) with minimal chromaticity shift (Δu'v' < 0.005).

In operating room applications, Rex LEDs provide shadow-free illumination with >50,000 lux at 1 meter distance while maintaining color temperature stability (±50K over 8 hours). The absence of IR emission reduces tissue heating, and the flicker-free operation (>10kHz PWM frequency) prevents visual fatigue during prolonged procedures.

For optimal performance, Rex LED arrays should be cleaned quarterly using the following protocol:

Power off the fixture and allow to cool to ambient temperature

Use compressed air (<30 psi) to remove loose particulate matter

Wipe optical surfaces with lint-free cloth moistened with isopropyl alcohol (70% concentration)

Avoid abrasive cleaners or solvents containing aromatic hydrocarbons

Proper heat sinking is critical for maintaining Rex LED performance:

Verify thermal interface material (TIM) integrity annually - replace if hardness exceeds Shore 00-50

Maintain heatsink fins clear of obstructions - airflow should exceed 2 m/s for passive systems

Monitor junction temperature using forward voltage method - should not exceed 110°C during operation

To ensure long-term driver compatibility:

Check for voltage ripple (<5% of nominal output) using true-RMS multimeter

Verify constant current regulation maintains within ±1% of set point

Inspect wire insulation for cracking or discoloration indicating overheating

Secondary optics require special attention:

Inspect silicone lenses annually for yellowing (YI <1.5 per ASTM E313)

Clean reflectors with pH-neutral detergent to maintain >92% reflectance

Check for lens delamination (bond strength >20 N/cm²) using peel test

Recommended service intervals for critical applications:

Monthly: Visual inspection for physical damage or discoloration

Quarterly: Photometric verification (maintain within 10% of initial values)

Annually: Full thermal and electrical system check

Every 5 years: TIM replacement and driver capacitor refresh