Transparent Led Film Display is an innovative display technology that combines high transparency with vibrant digital content projection. Unlike traditional LED screens that block all background visibility, these displays maintain 50-85% transparency while delivering bright, dynamic visuals. The technology utilizes ultra-thin (2-5mm thickness) film embedded with micro-LED chips (pixel pitches ranging from P3.9 to P10) that are virtually invisible when not illuminated.

Key technical specifications:

Transparency: 50-85% (depending on model and content brightness)

Brightness: 4000-6000 nits (adjustable for day/night operation)

Contrast Ratio: 5000:1 to 10000:1

Viewing Angle: 160° horizontal and vertical

Refresh Rate: 3840Hz (eliminating flicker)

Power Consumption: 150-300W/m² (50% less than conventional LED displays)

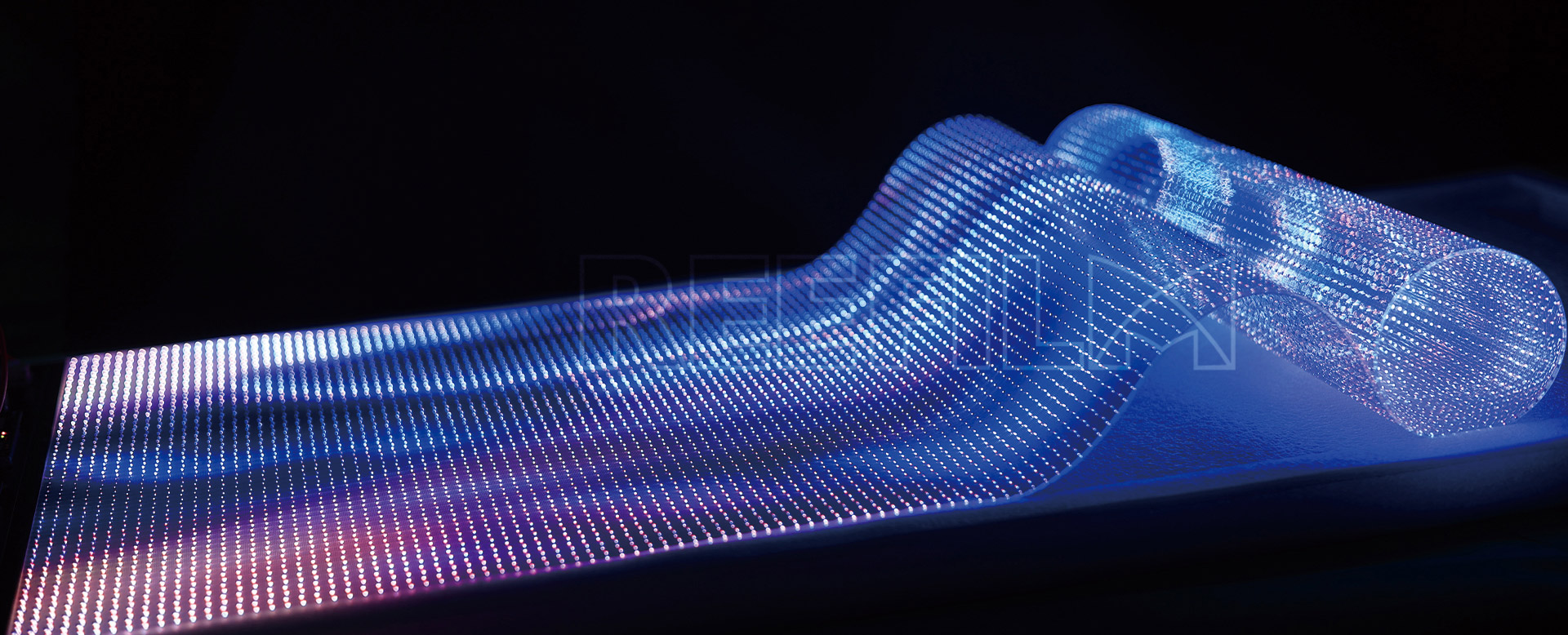

The transparent LED Film represents a breakthrough in display technology with several distinctive features:

1. High Transparency with Display Capability

The display maintains 70-85% light transmission in off-state, allowing clear view-through of background objects. When activated, it achieves 5000 nits peak brightness while preserving approximately 50% transparency, creating a unique augmented reality effect.

2. Ultra-Thin and Flexible Design

With a thickness of just 2-5mm and weight of 3-8kg/m², the film can be applied to various surfaces including curved glass. The bending radius can reach R1000mm for certain models, enabling creative architectural integration.

3. Energy Efficiency

The transparent nature reduces backlight requirements, resulting in 30-50% lower power consumption compared to conventional LED displays. Advanced heat dissipation design maintains surface temperature below 45°C during continuous operation.

4. Environmental Resistance

High-quality models feature IP65 waterproof rating for outdoor use, with operating temperatures ranging from -30°C to 60°C. The UV-resistant film maintains >90% brightness after 50,000 hours of operation.

The unique properties of transparent LED film displays enable diverse applications across multiple industries:

Retail and Commercial Spaces

High-end retail stores utilize P4.8-P7.8 pitch transparent displays on storefront windows, achieving 60% transparency while showcasing dynamic promotions. Shopping malls deploy large-scale installations (up to 100m² continuous displays) as interactive digital signage.

Architectural Integration

Modern buildings incorporate transparent LED films in curtain wall systems, transforming glass facades into media surfaces without compromising natural light. The technology enables 30-50% energy savings compared to traditional building lighting systems.

Museum and Exhibition Displays

Cultural institutions use P3.9-P5.9 high-resolution films to overlay digital information on physical artifacts, maintaining 75% transparency for unobstructed viewing. The 4000:1 contrast ratio ensures vivid content visibility in bright environments.

Transportation Hubs

Airports and train stations install transparent wayfinding systems with 5000 nits brightness for sunlight-readable information displays. The 160° viewing angle ensures visibility from multiple directions.

Automotive and Showroom Applications

Car manufacturers deploy curved transparent displays on showroom windows with R1500mm bending radius, creating immersive product presentations. Some luxury vehicles integrate the technology into heads-up displays with 0.1ms response time.

Proper maintenance ensures optimal performance and longevity of transparent LED film displays:

1. Cleaning Procedures

Use only alcohol-free cleaning solutions with <5% concentration of mild detergent. Apply with microfiber cloths (GSM 300-400) using <3N pressure. Never use abrasive materials or high-pressure sprays (>1 bar). Clean at 30-45° angle to the surface to prevent liquid ingress.

2. Environmental Controls

Maintain ambient temperature between 10°C-35°C and humidity at 30%-70% RH. For outdoor installations, ensure proper ventilation with ≥10cm air gap behind the display. Avoid direct exposure to >100,000 lux sunlight for extended periods.

3. Electrical Maintenance

Perform monthly voltage checks on power supplies (tolerance ±5% of rated voltage). Inspect connectors for corrosion every 3 months. Use surge protectors with ≤1ns response time for power stabilization.

4. Pixel Maintenance

Run pixel refresh cycles every 500 hours of operation to maintain uniform brightness. For displays operating >12 hours/day, implement 10% brightness reduction during nighttime operation to extend LED lifespan.

5. Software Updates

Update control software quarterly to ensure compatibility with latest video formats (up to 8K@60Hz input). Calibrate color profiles using spectrophotometers every 6 months to maintain ΔE<3 color accuracy.

6. Professional Inspections

Schedule annual professional inspections including thermal imaging (hot spots >65°C indicate potential issues) and power distribution analysis (±2% variance across modules). For critical installations, conduct vibration tests at 5-500Hz frequency to assess structural integrity.