An LED See-Through Screen is a cutting-edge display technology that combines high transparency with vivid digital content presentation. These screens typically feature a transparency rate between 50-90%, allowing viewers to see both the displayed content and the environment behind the screen simultaneously. The pixel pitch ranges from P3.9 to P10, with brightness levels adjustable from 1500 to 6000 nits to accommodate various lighting conditions. Advanced models incorporate 3840Hz refresh rates and 16-bit color processing, delivering smooth motion and accurate color reproduction while maintaining transparency.

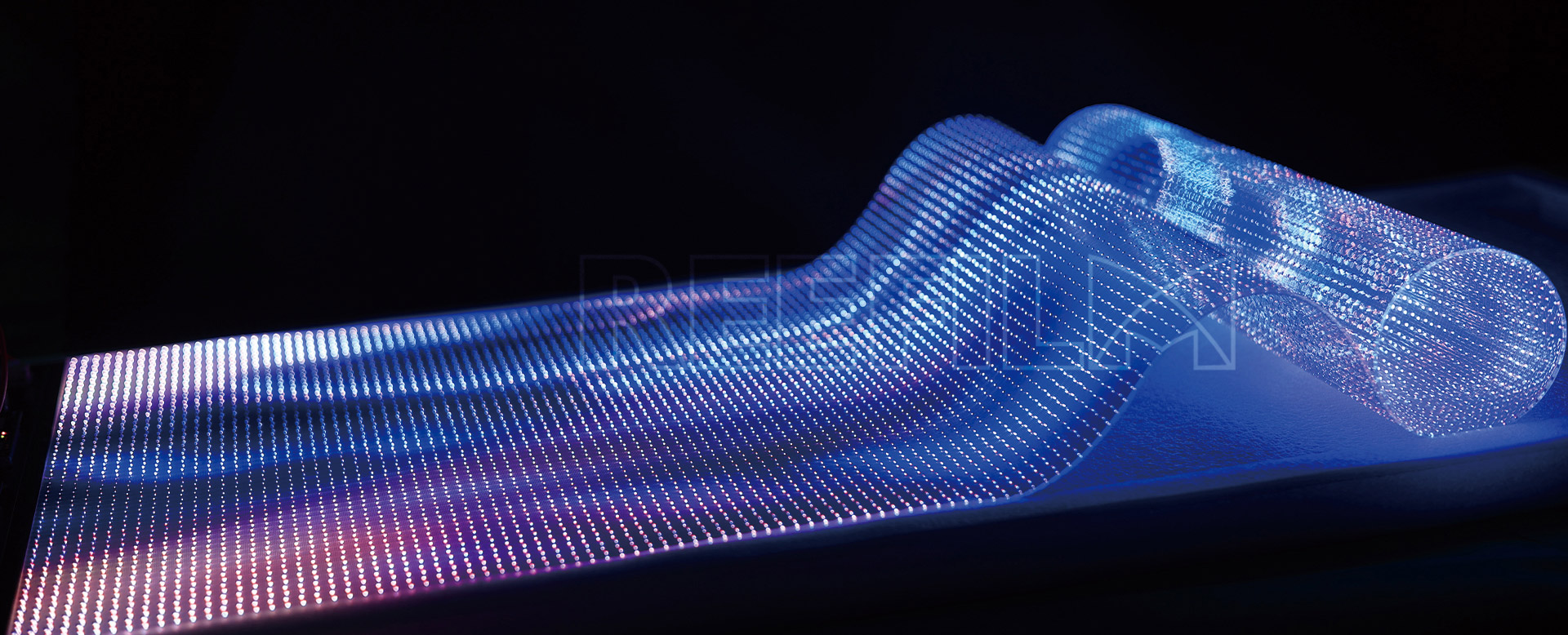

The unique design of see-through LED panels utilizes fine LED strips or micro-LED arrays with specialized mounting structures that minimize obstruction of the background view. This creates a striking visual effect where digital content appears to float in mid-air while preserving visibility of the physical space behind the display.

The most distinctive feature of see-through LED screens is their ability to maintain visibility through the display. Premium models achieve 85-90% transparency while still delivering bright, vibrant images. This is accomplished through innovative panel designs that space LED elements widely apart while using ultra-thin (2-3mm diameter) LED beads and transparent conductive materials.

Despite their transparent nature, these displays offer impressive 5000:1 contrast ratios and adjustable brightness up to 6000 nits for outdoor applications. The latest models feature automatic brightness sensors that adjust output based on ambient light conditions, maintaining optimal visibility while conserving energy.

Advanced optical designs ensure consistent image quality across 160-degree horizontal and vertical viewing angles without color shift or brightness degradation. This is achieved through specialized lens designs and LED chip configurations that distribute light evenly across wide angles.

Modern see-through LED screens consume 30-40% less power than conventional LED displays of similar size, thanks to intelligent power management systems and the reduced number of LEDs required for transparent operation. Some models feature solar panel integration for additional energy savings.

See-through LED screens revolutionize storefront displays by allowing retailers to showcase digital promotions while maintaining visibility of merchandise inside. High-end fashion brands utilize P4.8 transparent displays with 80% transparency for interactive window shopping experiences that blend digital content with physical products.

Modern buildings incorporate transparent LED facades as both aesthetic elements and functional displays. The P6.25 mesh-type transparent screens are particularly popular for building envelopes, providing 70% transparency while displaying dynamic content without compromising natural light penetration.

Cultural institutions employ P3.9 fine-pitch transparent displays to overlay digital information on physical artifacts. These systems typically operate at 3500 nits brightness with 10,000:1 contrast ratios to ensure readability in controlled lighting environments.

Airports and train stations install P8 Transparent LED Screens with 5000 nits brightness for wayfinding and information displays that don't obstruct passenger flow visibility. The screens feature IP65-rated protection against dust and moisture in these high-traffic areas.

Car dealerships utilize curved Transparent Led Displays with R5000mm bending radius to showcase vehicle features while maintaining full visibility of the automobiles. These specialized displays offer 75% transparency and can withstand -30°C to 60°C operating temperatures.

Transparent Led Screens require specialized cleaning to maintain optical clarity. Use alcohol-free cleaning solutions with <5% surfactant="" concentration="">and microfiber cloths with <100gsm weight="">. Clean in parallel strokes with <3n pressure="">to avoid damaging the transparent conductive layers. Perform cleaning bi-weekly for indoor installations and weekly for outdoor applications.

For outdoor installations, ensure the screen operates within its specified -20°C to 50°C temperature range and 10-90% humidity levels. Install UV-protective coatings in high-sunlight areas to prevent material degradation. Maintain 50cm minimum clearance behind the screen for proper airflow and heat dissipation.

Conduct monthly inspections of power supplies and data connections. Check for voltage fluctuations >5% and ensure all connections meet IP54 standards minimum. Replace power cables showing >0.5Ω resistance increase over initial measurements. Calibrate brightness sensors quarterly to maintain optimal performance.

Monitor for dead pixels monthly using RGB test patterns. Replace modules showing >5% pixel failure within warranty periods. For fine-pitch (P4.8 or smaller) displays, use 100x magnification tools for detailed inspection. Maintain replacement stock of 2% of total modules for critical applications.

Update control software quarterly to ensure compatibility with latest media formats. Optimize content for transparency by maintaining 30-40% black space in designs. For 24/7 operation, implement pixel shifting algorithms to prevent burn-in and schedule 4-hour rest periods weekly at 10% brightness.

Previous: P8 Outdoor LED Display