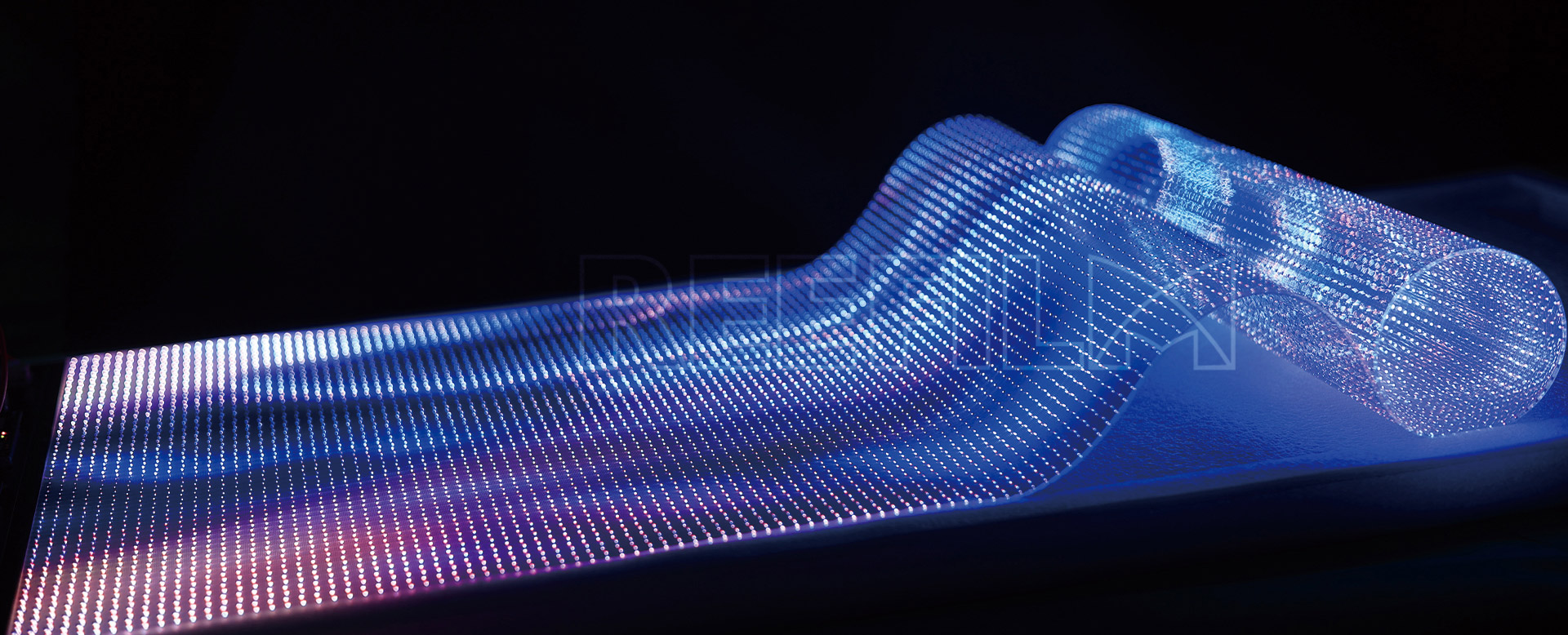

LED Glass Film is an innovative Transparent Display technology that combines the functionality of traditional glass with advanced LED illumination. This ultra-thin film, typically measuring between 0.3mm to 1.2mm in thickness, contains embedded micro-LED arrays with pixel pitches ranging from P1.2 to P10, offering resolutions up to 1920×1080 pixels. The technology achieves 70-90% transparency when inactive and maintains 500-1500 nits brightness when illuminated, with a contrast ratio exceeding 5000:1. Operating within a wide temperature range of -20°C to 60°C, these films consume approximately 50-100W per square meter and have a lifespan of 50,000-100,000 hours.

Transparency: 70-90% light transmission when off

Brightness: 500-1500 nits (adjustable)

Resolution: Up to Full HD (1920×1080)

Pixel Pitch: From P1.2 to P10

Viewing Angle: 160° horizontal and vertical

Response Time: <1ms

Power Consumption: 50-100W/m²

Operating Temperature: -20°C to 60°C

LED Glass Film transforms storefront windows into interactive displays while maintaining visibility into the store. The technology's 80-90% transparency allows natural light penetration while displaying promotional content with 16.7 million colors at 60Hz refresh rates. Major brands utilize these for window campaigns that achieve 30-50% higher engagement than traditional displays.

In smart buildings, LED Glass Film serves as dynamic facades with IP65-rated weather resistance. The 0.5mm ultra-thin profile enables retrofitting on existing glass structures without structural modifications. Some installations cover areas exceeding 100m² with seamless tiling technology.

Airports and train stations deploy LED Glass Film for wayfinding systems that maintain 72% transparency while displaying real-time information. The 5000:1 contrast ratio ensures readability in various lighting conditions, with some systems incorporating capacitive touch functionality.

Premium vehicles integrate curved LED Glass Film for head-up displays (HUDs) with 1200cd/m² brightness and 0.1ms response time. The technology withstands automotive temperature ranges from -40°C to 85°C and meets ISO/TS 16949 standards.

Hospitals utilize antimicrobial LED Glass Film with 99.9% bacterial reduction properties for interactive patient information systems. The anti-glare surface treatments reduce eye strain in clinical lighting conditions.

For optimal performance, clean the surface monthly using:

Isopropyl alcohol (70% concentration) or specialized display cleaners

Microfiber cloths with <100gsm density

Apply cleaning solution to the cloth, not directly on the film

Use <5N/cm² pressure during cleaning

Maintain ambient conditions within:

Temperature: 10°C to 40°C (operational)

Humidity: 20% to 80% RH (non-condensing)

Avoid direct >100,000 lux sunlight exposure for prolonged periods

For power systems:

Verify stable power supply within ±5% of rated voltage

Check connections every 6 months for corrosion

Measure current draw to detect potential issues (should remain within ±10% of specifications)

Regularly update control software to:

Maintain compatibility with HDCP 2.2 and DisplayPort 1.4 standards

Implement new PWM dimming algorithms for reduced flicker

Optimize color calibration (Delta E <3)

For installations with seasonal use:

Store in anti-static packaging

Maintain 40-60% RH in storage

Power on periodically (every 3 months) to prevent capacitor degradation

Previous: P6 Led Panel Price

Next: P8 Outdoor LED Screen