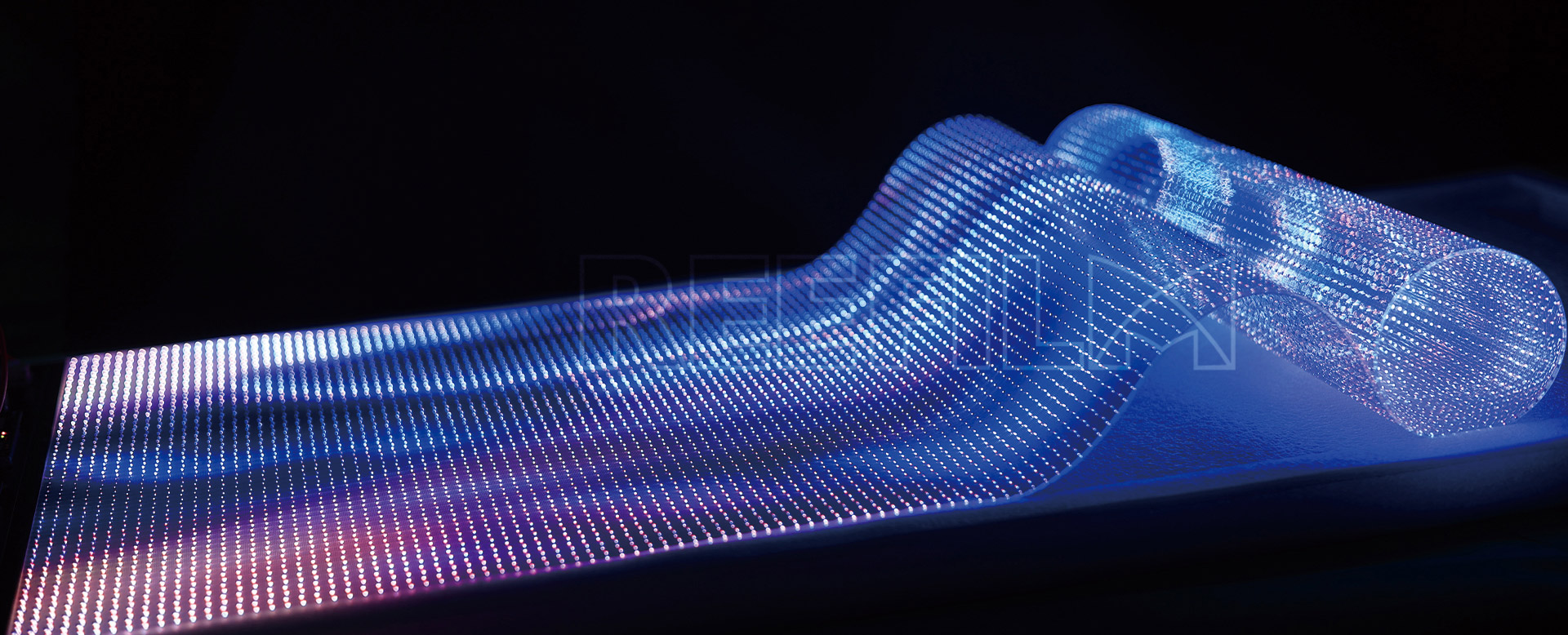

Transparent Led Film is an innovative display technology that combines high transparency with dynamic digital content display capabilities. This cutting-edge solution features ultra-thin (1.5-3mm thickness), lightweight (1.2-2.5kg/m²) panels that maintain 70-85% transparency while displaying vibrant content with 500-5000 nits brightness and 16.7 million color capacity. The technology utilizes advanced micro-LED chips (P1.2-P3.9 pixel pitch) embedded in transparent conductive films, achieving 80-90% transmittance for glass substrates.

Key technical specifications include:

Viewing angle: 140-160 degrees (horizontal and vertical)

Refresh rate: ≥3840Hz for flicker-free performance

Contrast ratio: 5000:1 to 10000:1

Power consumption: 150-300W/m² depending on brightness

Lifespan: 50,000-100,000 hours (L70)

The Transparent Led film boasts several remarkable technical characteristics that set it apart from conventional display solutions:

Optical Performance: With a color gamut covering ≥95% NTSC and grayscale of 14-16bit, the film delivers exceptional image quality. The LED density ranges from 65,000 to 250,000 pixels/m², ensuring sharp visuals even at close viewing distances.

Environmental Adaptability: The film operates within a temperature range of -20°C to 60°C with IP54-IP65 protection against dust and moisture. It maintains stable performance under 85% RH humidity conditions.

Mechanical Properties: The flexible substrate allows for bending radius down to 50mm, enabling curved installations. The surface hardness reaches 3H-6H (pencil hardness scale) with anti-glare treatment reducing reflectivity to <5%.

Electrical Characteristics: Operating at DC 5V/12V/24V with low voltage drive technology, the system achieves ≤0.5% brightness deviation across the entire surface. The response time is <1ms, eliminating motion blur for dynamic content.

Transparent LED Film finds applications across diverse industries due to its unique combination of transparency and display capabilities:

Retail & Commercial: High-end storefront windows (maintaining 75% visibility of merchandise), shopping mall atriums, and interactive product displays with 10-60% energy savings compared to traditional digital signage.

Architecture & Design: Smart building facades (covering 100-500m² surfaces), glass curtain walls, and interior partitions providing both privacy (switchable opacity) and information display.

Transportation: Airport/train station information screens (500-2000cd/m² for daylight visibility), subway window advertisements, and automotive HUD systems with ≤1ms latency for real-time data.

Exhibitions & Museums: Interactive exhibit cases (10-100 touch points support), augmented reality displays, and historical artifact presentations with UV-free illumination (wavelength >450nm).

Hospitality: Restaurant menu boards, hotel lobby partitions, and conference room glass walls with 4K-8K resolution at viewing distances of 0.5-10 meters.

Proper maintenance ensures optimal performance and extends the lifespan of transparent LED film installations:

Cleaning Procedures: Use isopropyl alcohol (<70%) or neutral pH cleaners with microfiber cloths (≤100gsm). Apply 5-10N/cm² pressure in unidirectional wipes. Avoid ammonia-based cleaners that may damage the ITO conductive layer.

Environmental Control: Maintain ambient temperature at 15-35°C with 40-70% RH. For outdoor installations, ensure proper ventilation (≥0.5m clearance) behind panels to prevent heat buildup exceeding 60°C.

Electrical Maintenance: Perform monthly checks on power supplies (voltage tolerance ±5%) and connections. Use surge protectors rated for 6kV/20kA minimum. Calibrate brightness sensors (0-100,000 lux range) quarterly for automatic adjustment.

Pixel Management: Run dead pixel compensation algorithms monthly (threshold ≤0.01% defective pixels). For persistent issues, use RGB calibration tools (accuracy ΔE<3) to maintain color uniformity.

Software Updates: Update control system firmware quarterly to maintain HDR10+/HLG compatibility and security patches. Backup configuration files (CRC-32 verified) before updates.

Preventive maintenance schedule:

Daily: Visual inspection for physical damage

Weekly: Surface dust removal with ionized air blowers

Monthly: Electrical system diagnostics

Quarterly: Full calibration and thermal imaging

Annually: Professional optical measurement

Previous: Clear Color Led Film

Next: P6 Led Panel Price