A Transparent LED Film Screen is an advanced display technology that combines high transparency with vibrant visual performance. Unlike traditional LED screens, these ultra-thin films allow light to pass through while displaying dynamic content. Key technical specifications include:

Transparency: 70-90% light transmission (e.g., 85% for ClearLED series)

Pixel Pitch: Ranging from P3.9 to P10 (3.9mm-10mm)

Brightness: 5,000-8,000 nits (adjustable for indoor/outdoor use)

Refresh Rate: ≥3,840Hz (eliminating flicker at high frame rates)

Viewing Angle: 160° horizontal/vertical (wide visibility)

Power Consumption: 30-50% lower than conventional LED displays

1. Optical Performance: Utilizing micro-LED chips (100-200μm) with SMD packaging, these screens achieve 16-bit color depth (281 trillion colors) while maintaining DCI-P3 98% color gamut coverage. The contrast ratio exceeds 10,000:1 even in high ambient light conditions.

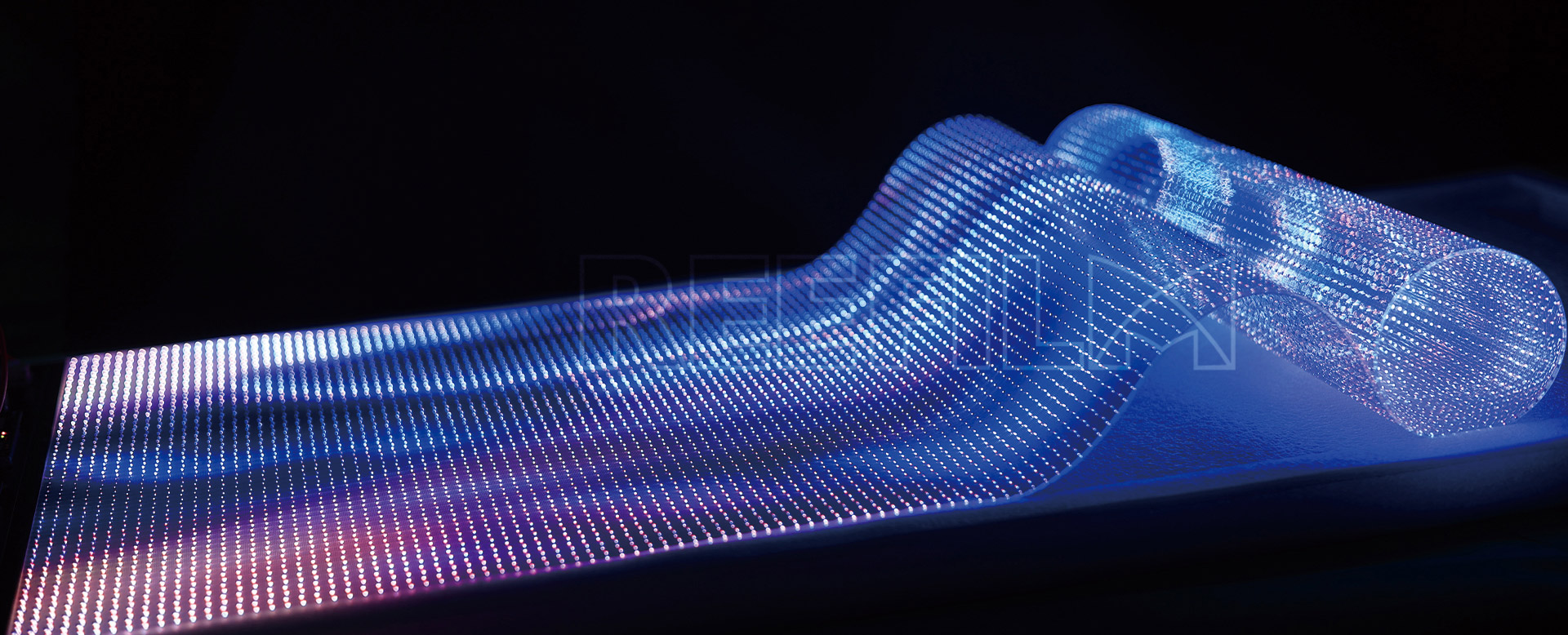

2. Structural Innovation: The screen thickness measures just 2-5mm with a weight of 3-8kg/m². The film substrate employs PET material with 89% transmittance and anti-glare coating (60° haze). Modular designs support curved installations with 15°-30° bending radius.

3. Environmental Adaptability: IP65-rated units operate in -30°C to 60°C temperatures with 95% humidity tolerance. The surface luminance uniformity achieves ≤5% deviation across the display area.

Installed on storefront windows (typically P6.7-P10 pitch), these screens maintain 75% visibility while showcasing promotions. Major brands report 37% higher engagement versus traditional posters.

Building facades utilize P4.8-P7.6 modules with 80% transparency, reducing HVAC load by 18% compared to conventional media walls while providing 24/7 content display.

Airports deploy P3.9-P5.9 screens at security checkpoints, achieving 550cd/m² brightness with 40% energy savings versus LCD alternatives. The 170° viewing angle ensures readability from multiple directions.

P5.2 transparent displays mounted on vehicle windows demonstrate interactive features while preserving showroom sightlines, increasing dwell time by 28% according to BMW dealership trials.

Ultra-fine P2.6-P3.9 modules overlay artifacts with 68% transparency, projecting contextual information without physical contact. The 4K resolution (3840×2160) maintains artifact visibility.

Use anhydrous alcohol (99.9% purity) with microfiber cloths (GSM 200-300) at 25°C ambient temperature. Apply <1N/cm² pressure in unidirectional strokes. Frequency: biweekly for indoor, weekly for outdoor installations.

Maintain relative humidity at 30%-70% with <0.1% condensation risk. For outdoor units, verify IP rating seals quarterly using 5kPa water jet tests.

Measure power supply stability (±5% voltage tolerance) monthly. Check grounding resistance (<4Ω) and LED driver currents (mA-level precision) using calibrated multimeters.

Run dead pixel compensation algorithms every 500 operating hours. For clusters >3 adjacent faulty pixels (0.01% occurrence), initiate module replacement at <25°C to prevent adhesive issues.

Update control firmware biannually, verifying compatibility with HDR10+ and 12-bit gamma correction tables. Maintain 30% spare capacity on content servers to prevent memory fragmentation.

Torque-check mounting hardware (typically 2.5-4Nm) during seasonal maintenance. For tensioned installations, verify 15-20kgf/m² stress uniformity using strain gauges.

| Parameter | Transparent Film LED | Conventional LED | OLED Glass |

|---|---|---|---|

| Transparency | 70-90% | 0% | 40-60% |

| PPI Density | 64-256 | 16-100 | 300-500 |

| Lifetime (L70) | 80,000h | 100,000h | 30,000h |

| Power (W/m²) | 300-500 | 700-1200 | 150-300 |

The mounting surface flatness must meet ≤2mm/m² tolerance. For glass substrates, ensure 6-12mm thickness with tempered or laminated construction. The air gap between film and glass should be 1.5±0.3mm for optimal heat dissipation (critical for >5,000nit operation).

Design for 30-50% opacity fill ratio to maintain transparency. Recommended color settings: sRGB mode with 2.4 gamma for indoor, Rec.709 with 2.2 gamma for outdoor. Motion content should limit to 60fps with 5ms persistence to prevent ghosting.

Previous: Soft Led Screen

Next: Indoor Led Panel Display