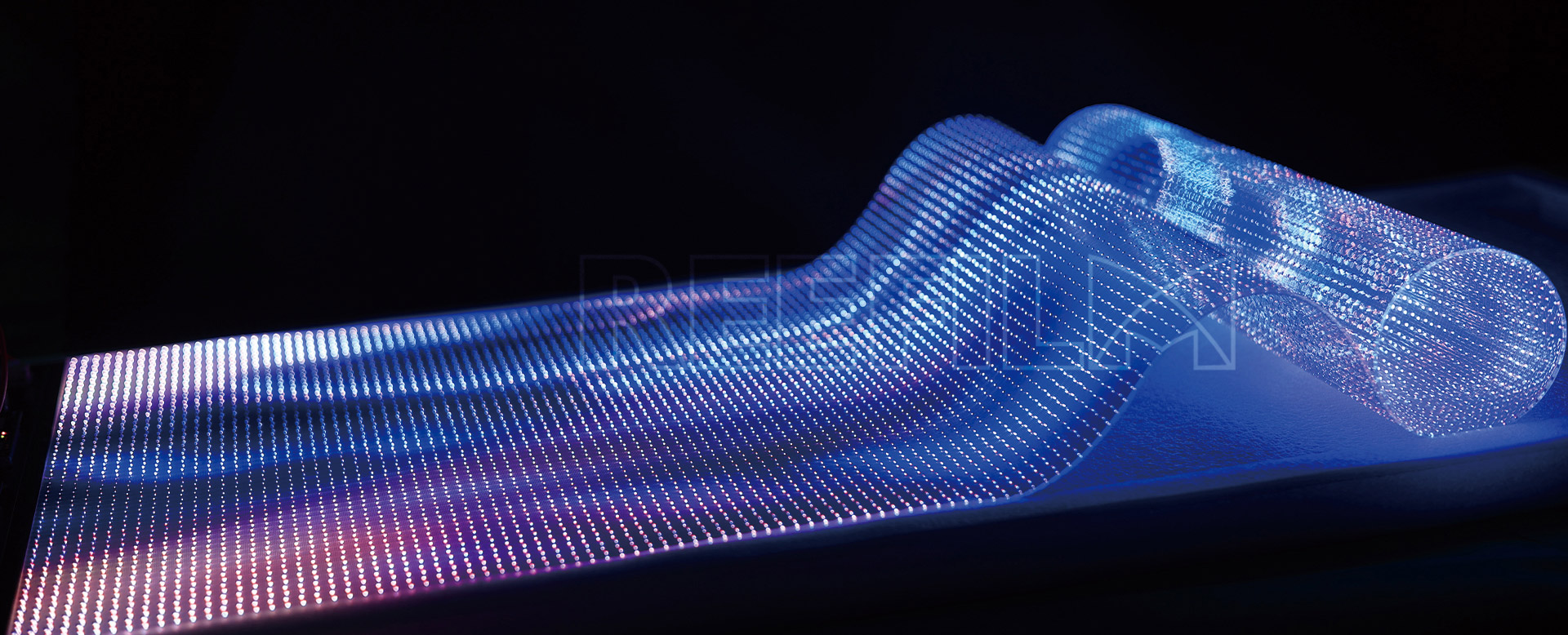

A Transparent LED Film Screen is an innovative display technology that combines high transparency with vibrant visual performance. Unlike traditional LED displays, these screens utilize ultra-thin, lightweight LED films that can be applied to glass surfaces while maintaining visibility through the screen. Key technical specifications include:

Transparency: Typically 70-90% light transmittance (e.g., 85% transparency for 5mm pixel pitch models)

Pixel Pitch: Ranges from 3.9mm to 10mm (e.g., P3.9, P5.6, P7.8, P10 options)

Brightness: 5000-8000 nits for daylight visibility

Viewing Angle: 160-178 degrees horizontal and vertical

Refresh Rate: ≥3840Hz for smooth video playback

Contrast Ratio: 5000:1 to 10000:1

Thickness: Only 2-5mm, weighing <5kg/m²

The Transparent LED Film Screen offers several distinctive features that set it apart from conventional display technologies:

1. High Transparency with Display Capability: With 70-90% transparency (measured at 550nm wavelength), these screens maintain building aesthetics while displaying content. The optical grade adhesive ensures minimal light diffusion (<3% haze).

2. Flexible Installation: The screen can be curved to radii as tight as 1000mm (for P5.6 models) and operates in temperatures from -20°C to 60°C with IP65 protection against dust and moisture.

3. Energy Efficiency: Consuming only 150-300W/m² (depending on content brightness), these screens are 30-50% more efficient than conventional LED displays. The modular design allows for individual pixel control to optimize power usage.

4. Superior Visual Performance: With 16-bit color processing (281 trillion colors), 1200-1500cd/m² typical brightness, and <3ms response time, the screens deliver cinema-quality imagery. The anti-glare treatment reduces reflections by up to 75% compared to standard glass.

1. Retail and Commercial Spaces: High-end stores use transparent LED films for interactive product displays (65% of luxury brands in Asia have adopted this technology). The screens can showcase products while maintaining store visibility, with typical installations spanning 5-50m² per location.

2. Architectural Integration: Modern buildings incorporate these displays in glass facades (up to 90% transparency) for dynamic branding. The 50000-hour lifespan (at 50% brightness) ensures long-term performance with minimal maintenance.

3. Museums and Exhibitions: The 8K resolution capability (for P3.9 models at optimal viewing distances) makes these screens ideal for detailed artifact presentations. The UV-resistant films (blocking 99% of UV rays) protect sensitive exhibits.

4. Transportation Hubs: Airports and train stations utilize the screens for wayfinding (visible from up to 30m distance for P7.8 models) without compromising natural light. The 24/7 operation capability with <0.1% dead pixels after 3 years makes them reliable for critical infrastructure.

5. Automotive Showrooms: Car dealerships use the technology for augmented reality displays (compatible with Unity and Unreal Engine) that overlay specifications on actual vehicles. The screens withstand vibrations up to 5.9m/s² without image degradation.

Proper maintenance ensures optimal performance and longevity of Transparent LED Film Screens:

1. Cleaning Procedures:

Use only isopropyl alcohol (<70% concentration) or specialized display cleaners

Apply with microfiber cloths (GSM 300-350) at 20-30°C ambient temperature

Maintain 0.5-1kg/cm² pressure during cleaning to avoid damaging the film

Clean bi-weekly in normal environments, weekly in high-pollution areas

2. Environmental Controls:

Maintain ambient humidity at 30-70% RH (non-condensing)

Ensure operating temperature remains within -20°C to 50°C

Limit direct sunlight exposure to <100,000 lux for >8 hours/day

3. Electrical Maintenance:

Perform monthly voltage checks (5V±0.25V for most models)

Calibrate color uniformity every 6 months (ΔE<3 tolerance)

Update firmware quarterly (current versions support HDR10+ and HLG)

4. Physical Inspection:

Check adhesive integrity annually (peel strength should remain >3N/25mm)

Inspect for dead pixels monthly (acceptable rate: <0.01% under warranty)

Verify waterproof seals every 3 months in outdoor installations

For optimal performance, schedule professional maintenance every 2000 operating hours (approximately quarterly for 24/7 installations). The mean time between failures (MTBF) typically exceeds 50,000 hours when properly maintained.

Previous: P6 Led Screen