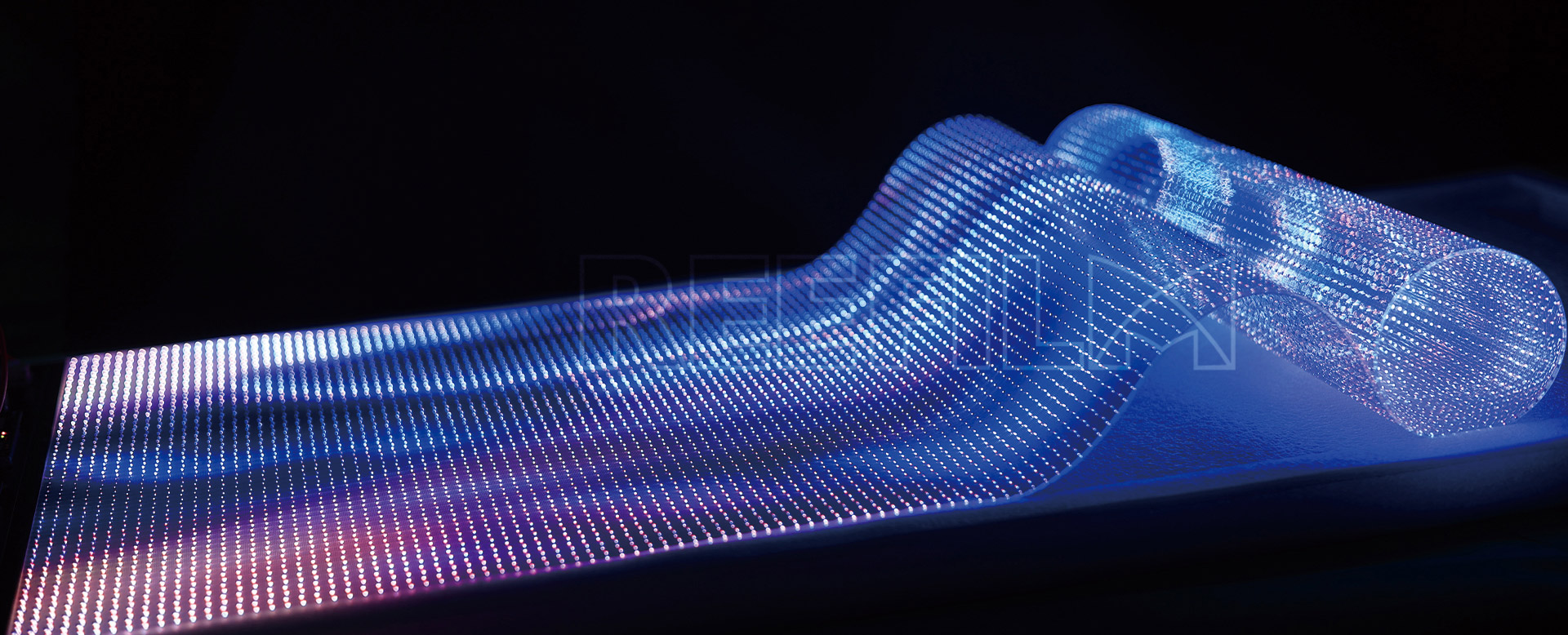

Flexible Transparent LED Screens represent a groundbreaking advancement in display technology, merging the dynamic visual capabilities of traditional LED displays with unprecedented physical properties. Unlike conventional LED screens that are rigid and opaque, these displays are built on transparent substrates, often using fine mesh materials or transparent conductive films, allowing light to pass through the inactive areas of the panel. The "flexible" aspect is achieved through innovative engineering, utilizing materials like polyimide or other flexible polymers that can withstand bending, curving, and even rolling to a certain degree without damaging the embedded micro-LED chips and circuitry. This combination of transparency and flexibility opens up a new dimension for digital signage and architectural integration, transforming ordinary glass surfaces into vibrant, dynamic canvases for information and art.

The core innovation of these screens lies in their unique set of physical and optical properties, each supported by precise technical data.

High Transparency

The most striking feature is their ability to remain see-through while displaying content. Typical transparency rates range from 65% to 90%, significantly higher than traditional LED displays which are 0% transparent. This is measured as the percentage of visible light that can pass through the screen material when it is powered off. A rate of 80% means the screen is nearly as clear as standard glass, ensuring that views and natural light are not substantially obstructed, making them ideal for retail windows and building facades.

Flexibility and Bendability

These screens are not flat, rigid panels. They can be bent to conform to curved architectural elements. The bending radius is a critical specification, indicating how tightly the screen can be curved without causing permanent damage to the LEDs or circuits. Advanced models offer a minimum bending radius of 500mm to 1000mm, allowing for installation on cylindrical columns, curved walls, and even undulating surfaces, creating immersive and organic visual experiences that were previously impossible.

Lightweight Construction

By eliminating the heavy metal cabinet structure of traditional LEDs and using lightweight materials, these screens offer a drastically reduced weight. The weight per square meter is typically between 8 kg to 15 kg, compared to 25-40 kg/m² for a standard SMD LED display. This reduced load is a critical advantage for installations on glass curtain walls, suspended setups, and historical buildings where structural load capacity is a major concern, often eliminating the need for expensive reinforcement.

High Brightness and Color Performance

Despite their transparency, they do not compromise on visual performance. To remain visible in direct sunlight, they boast high luminance levels, typically between 5,000 to 7,500 nits. They also maintain excellent color gamut, often covering ≥110% of the NTSC standard, ensuring vibrant, accurate, and saturated colors for captivating visual content.

Fine Pixel Pitches

Resolution is determined by the pixel pitch—the distance between the centers of two adjacent pixels. Flexible transparent LEDs are available in a range of pitches, from coarser options like P6 (6mm) suitable for larger viewing distances, down to ultra-fine pitches like P2.5 (2.5mm) or even smaller for close-viewing applications, ensuring sharp and detailed imagery even as the technology allows for transparency.

The unique attributes of flexible transparent LED screens have catalyzed their adoption across a wide spectrum of industries.

Retail and Commercial Displays

They are revolutionizing retail window displays. Stores can apply them directly onto glass storefronts, creating dynamic advertisements that attract attention without completely blocking the view of the interior and the merchandise, effectively merging the digital and physical shopping experience.

Corporate and Architectural Integration

In modern architecture, they are embedded into glass walls, partitions, and skybridges in corporate lobbies, turning entire facades into media art pieces or information hubs. Their lightweight nature makes them safe for glass integration, and their transparency maintains the building's aesthetic and openness.

Stage and Event Productions

The entertainment industry leverages their flexibility and semi-transparency to create stunning stage backdrops. They can be shaped into curved screens, allowing for creative set designs. Their see-through quality enables performers to be seen behind the screen, facilitating layered visual effects and augmented reality-like experiences for the audience.

Museums and Exhibitions

Museums use them for interactive exhibits and informational displays. The transparent screen can be placed in front of an artifact, showing digital information, reconstructions, or animations that overlay and enhance the physical object behind it without fully obscuring it.

Transportation Hubs and Automotive

Airports and train stations use them for wayfinding and advertising on glass surfaces. In the automotive sector, concepts for transparent LED screens in car windows for passenger entertainment and heads-up displays are being explored, showcasing the technology's potential for future mobility.

Proper maintenance is crucial for ensuring the longevity, performance, and safety of a flexible Transparent Led Display. The procedures differ significantly from those for traditional LEDs due to their delicate nature.

Routine Cleaning Procedures

Dust, dirt, and fingerprints can diminish transparency and brightness. Cleaning should be done gently and carefully. Always power off and disconnect the screen before cleaning. Use a soft, dry, lint-free microfiber cloth to gently wipe the surface. For more stubborn smudges, slightly moisten the cloth with deionized water or isopropyl alcohol ( concentration below 75%). Never spray liquid directly onto the screen. Apply minimal pressure to avoid damaging the LEDs or flexing the panel excessively during cleaning. Avoid any abrasive cloths, paper towels, or chemical solvents, which can scratch the surface or damage the protective coating.

Environmental Considerations

Although many Flexible LED Screens are designed for indoor use, some are rated for outdoors. It is critical to understand the screen's IP rating (Ingress Protection). For outdoor installations, a rating of IP65 or higher is necessary to protect against dust and low-pressure water jets. Even indoors, the environment should be controlled. Avoid environments with excessive humidity, extreme temperature fluctuations, or corrosive gases. The flexibility of the screen also means that installations must be secure and stable to prevent excessive or constant vibration, which could fatigue the materials and solder joints over time.

Handling and Storage Best Practices

The flexible property does not mean the screen is indestructible. Bending should only be performed during the initial installation according to the manufacturer's specified radius and should not be done repeatedly. When handling, always support the entire screen evenly. Avoid poking, pressing, or placing heavy objects on the surface. For transportation and storage, keep the screen in its original protective packaging and store it in a dry, flat, and temperature-controlled environment. If the screen is rolled, it should be stored on a dedicated reel to prevent creasing or cracking.

Software and Hardware Checks

Regularly inspect the integrity of the display. Look for any dead pixels, discolored sections, or physical damage to the surface. Ensure that all data and power connections are secure. Use the manufacturer's provided software to run diagnostic tests and to ensure the content being displayed is optimized for the screen's unique transparent properties, often utilizing black backgrounds effectively to maximize transparency. Keeping the control system firmware updated can also improve performance and stability.

Previous: Transparent Flexible Led Display