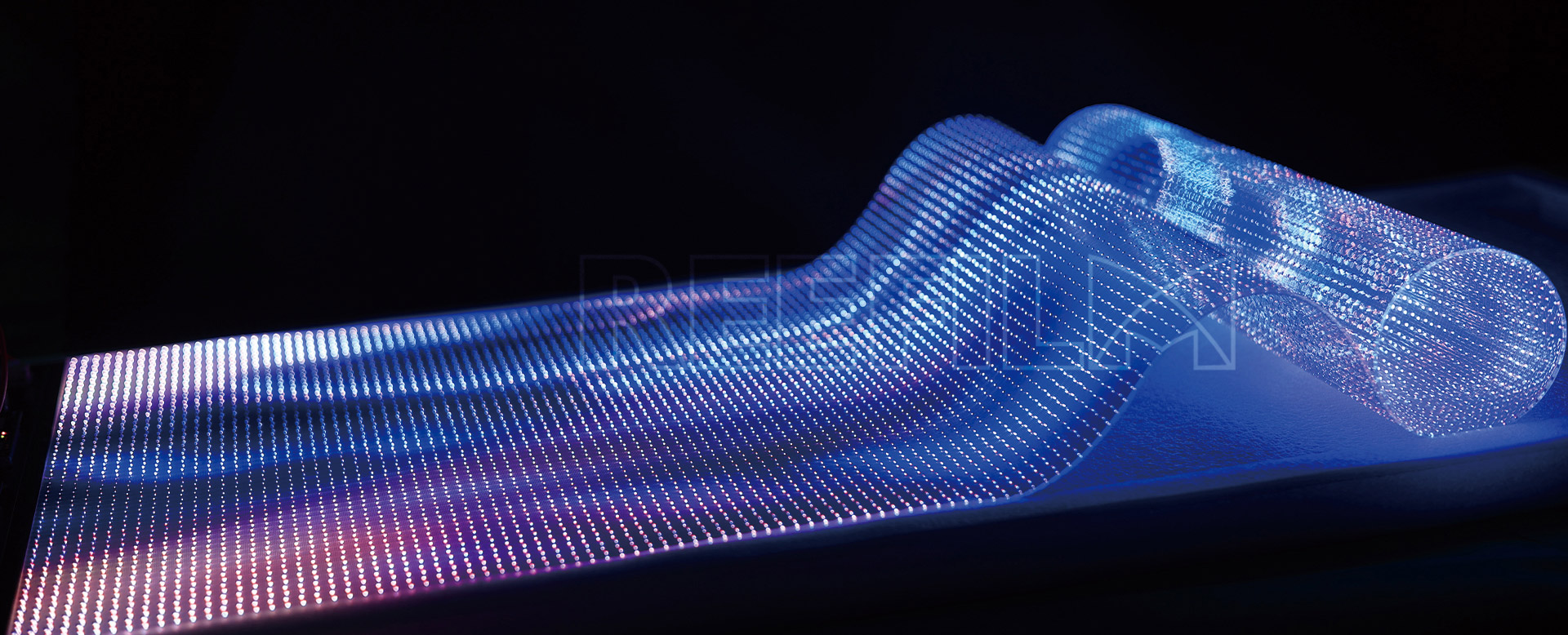

Transparent Flexible Led Display represents a revolutionary advancement in visual technology, merging the properties of transparency and malleability with high-resolution illumination. Unlike traditional LED screens that are rigid and opaque, these displays are constructed using innovative materials like flexible printed circuit boards (PCBs) and transparent conductive electrodes, often made from materials like Indium Tin Oxide (ITO) or silver nanowire. The core innovation lies in the use of microscopic LEDs, typically Mini-LEDs or Micro-LEDs, which are sparse enough to allow light to pass through the panel. A key performance metric is its transparency rate, which can range from 60% to 90%, meaning the majority of background scenery remains visible. This is coupled with a remarkable flexibility, often capable of withstanding a bending radius as low as 10mm without damage to the circuitry or LEDs. Despite their see-through nature, these displays achieve impressive brightness levels, often exceeding 5,000 nits for outdoor applications, ensuring vivid visibility even in direct sunlight. They also maintain a high contrast ratio, frequently over 10,000:1, for deep blacks and vibrant colors. Pixel pitches can vary widely, from coarse P10 (10mm) for large-scale installations to fine P2.5 (2.5mm) for closer viewing distances, all while operating within a wide temperature range of -20°C to 60°C.

The unique characteristics of Transparent Flexible Led Displays unlock a multitude of applications across various industries.

Retail and Commercial Facades: They are installed on store windows, allowing retailers to project dynamic advertisements and product information without completely obstructing the view into the store. This enhances customer engagement while maintaining an open and inviting atmosphere.

Architectural Integration and Building Skins: Architects use these displays to turn entire building facades or interior walls into dynamic media surfaces. Their flexibility allows them to be fitted onto curved structures, creating immersive architectural lighting and art installations that blend digital content with the physical environment.

Museums and Exhibitions: In museums, these displays serve as interactive information kiosks or overlays on exhibit cases. Visitors can see digital annotations and multimedia content superimposed on the actual artifacts, enriching the educational experience without physical barriers.

Stage and Event Production: For concerts, theater shows, and corporate events, these displays are used as see-through backdrops or set pieces. Performers can be seen behind the screen, with graphics and effects layered in front of them, creating a compelling depth effect and augmented reality experiences.

Automotive and Transportation: Concept cars and high-end vehicles incorporate flexible transparent displays into windshields as Head-Up Displays (HUDs) or as interactive partitions within the cabin, providing information while preserving visibility and a sense of space.

High-Tech Showrooms and Control Rooms: They function as futuristic interactive partitions or data visualization screens in command centers, allowing operators to see critical data while maintaining a line of sight with their team or other monitoring screens.

Proper maintenance is crucial for ensuring the longevity and optimal performance of a Transparent Flexible LED Display. The following procedures should be followed meticulously.

Dust, fingerprints, and other contaminants can significantly reduce transparency and brightness. Cleaning should be performed regularly with the power turned off and the display completely cooled down.

Tools: Use a soft, lint-free cloth, such as a microfiber cloth. For stubborn stains, lightly moisten the cloth with isopropyl alcohol (IPA) with a concentration below 75% or deionized water. Never spray liquid directly onto the screen.

Technique: Gently wipe the surface in one direction with minimal pressure. Avoid circular motions or using abrasive materials like paper towels, which can cause micro-scratches on the protective layer.

The operating environment directly impacts the display's lifespan.

Temperature and Humidity: Operate and store the display within the manufacturer's specified range, typically 20°C to 30°C with humidity between 40% RH and 60% RH. Avoid rapid temperature changes to prevent condensation inside the modules.

Sunlight and Heat Exposure: While bright for outdoor use, prolonged direct exposure to intense UV radiation and heat can accelerate the aging of materials. If possible, install with some shading or use displays rated for high UV resistance.

The "flexible" nature requires careful handling to avoid permanent damage.

Bending and Curving: Always adhere to the specified minimum bending radius. Bending the screen beyond this limit can fracture the internal circuits and LEDs. Bending should be performed gently and evenly across the panel.

Physical Impact and Pressure: Avoid sharp impacts, poking, or placing heavy objects on the display surface. The flexible substrate is more vulnerable to punctures than rigid glass or metal.

Static Electricity (ESD): Handle modules and circuits in an ESD-safe environment. Use grounded wrist straps to prevent electrostatic discharge from damaging the sensitive Micro-LED components.

By adhering to these detailed maintenance protocols, the advanced features of the Transparent Flexible LED Display can be preserved, ensuring it continues to deliver stunning visual experiences with a long service life, thereby protecting the significant investment it represents.

Previous: Led Transparent Film Screen