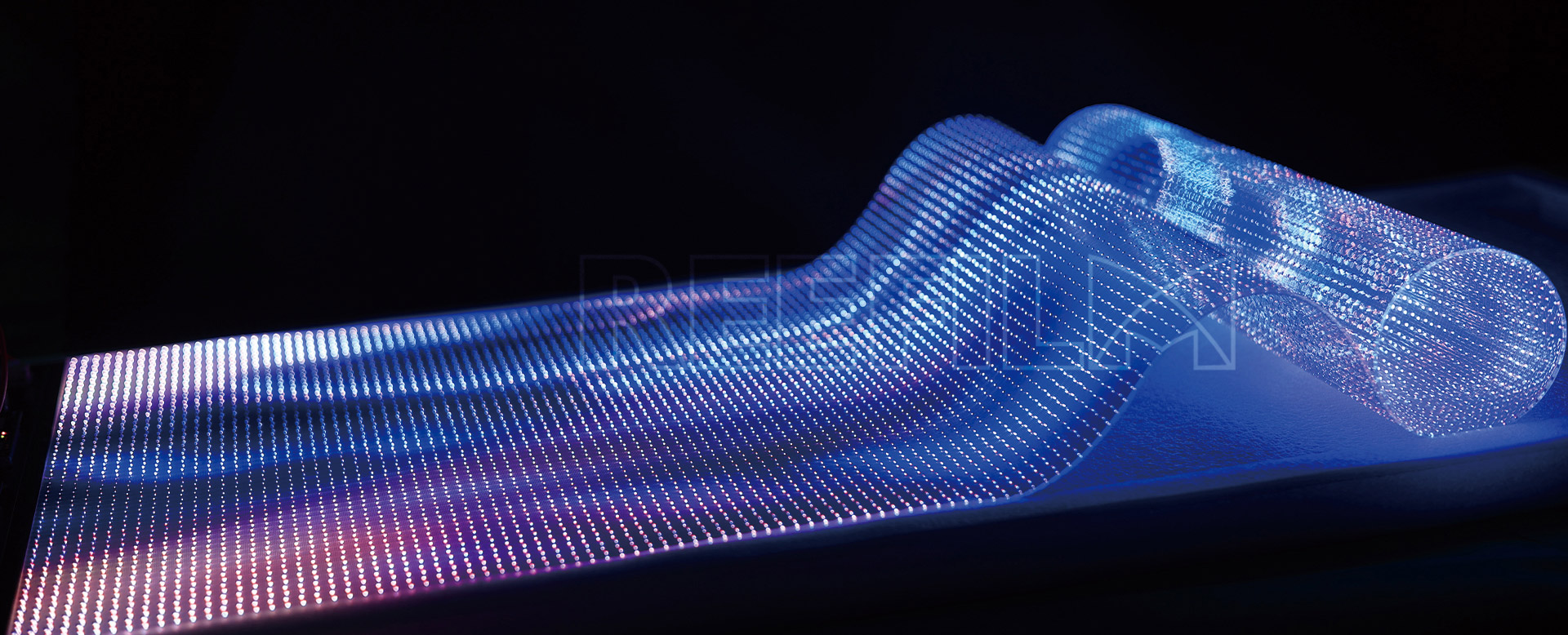

Clear Color LED Film is an innovative Transparent Display technology that combines high transparency with vibrant color reproduction. This cutting-edge solution consists of ultra-thin LED modules embedded between transparent conductive layers, typically using indium tin oxide (ITO) or silver nanowire technology with a transparency rate of 65-85% when powered off. The film maintains a slim profile of just 0.8-2.5mm thickness while delivering exceptional visual performance.

Unlike traditional Led Displays that block all background visibility, Clear Color LED Film preserves see-through qualities with minimal light obstruction, making it ideal for applications where maintaining visibility is crucial while adding dynamic digital content.

The film delivers ≥85% NTSC color gamut coverage with a contrast ratio of 5000:1 in typical viewing conditions. The high transparency version achieves ≥80% light transmittance while maintaining 1000-1500 nits brightness for excellent visibility even in direct sunlight environments.

Available in various pixel pitches from P1.2 to P10, with the high-resolution versions offering ≥100 PPI (pixels per inch). The advanced models feature 4K resolution (3840 × 2160) on large format installations while maintaining transparency.

Utilizing micro-LED technology, the film consumes 30-50% less power than conventional Led Displays of similar size, with typical power consumption of 150-300W/m² depending on brightness settings and content.

The film is rated for IP65 or higher protection against dust and moisture, with an operational temperature range of -30°C to 60°C. The surface hardness reaches ≥7H on the pencil hardness scale, and the product lifespan exceeds 50,000 hours to 70% initial brightness.

Certain models offer bending radius as low as 50mm for curved installations, with weight typically under 3kg/m², making it suitable for glass facade applications without requiring structural reinforcement.

3.1 Retail and Commercial Displays

Used in storefront windows as interactive digital signage with touch sensitivity up to 10-point multi-touch, maintaining visibility of merchandise while displaying promotional content. The 120° wide viewing angle ensures content remains visible from various positions in retail environments.

3.2 Architectural Integration

Implemented in building facades as media architecture elements, transforming glass surfaces into dynamic displays without compromising natural light transmission. The ultra-thin profile (≤2mm) allows seamless integration with existing glazing systems.

3.3 Transportation Hubs

Deployed in airports and train stations as wayfinding displays that maintain visibility of operational areas. The high brightness (≥1500 nits) ensures readability in brightly lit environments, while the wide temperature tolerance suits various climate conditions.

3.4 Automotive and Showrooms

Used in vehicle showrooms as augmented reality displays on car windows, showcasing technical specifications without obscuring the vehicle. The fast response time (<5ms) enables smooth video playback for dynamic content presentation.

3.5 Museum and Exhibition Spaces

Implemented as interactive exhibit overlays that provide additional information while maintaining view of artifacts. The anti-reflective coating reduces glare in brightly lit exhibition environments.

Use only isopropyl alcohol (70% concentration or less) or specialized display cleaning solutions. Apply with a microfiber cloth (GSM ≥250) using gentle, linear motions. Avoid circular wiping patterns that may cause micro-scratches on the surface coating.

Maintain ambient humidity between 30-70% RH to prevent moisture damage. For outdoor installations, perform quarterly inspections of sealing integrity, particularly checking for ≥1mm edge sealant integrity around the perimeter.

Conduct bi-annual power supply checks, verifying stable output within ±5% of rated voltage. Monitor for dead pixels (allowable ≤0.0001% of total pixels) and schedule professional repair if exceeding tolerance.

Regularly update display firmware (quarterly recommended) to maintain optimal performance. For content, maintain color calibration every 6 months using professional spectrophotometers to ensure ΔE<3 color accuracy.

When storing unused panels, maintain in anti-static packaging at 15-25°C with 40-60% RH. Rotate stock every 6 months to prevent adhesive degradation, and perform power-on tests every 3 months for 2 hours to maintain capacitor health.

Previous: Flexible Led Screen Panel

Next: Transparent Led Film